How Do You Print on Titanium?

If you are wondering how to print on titanium, there are several ways to get started. The first step is to create a design. The design file should be compatible with your titanium 3D printer. Most programs are designed for standard 3D printers, so you can simply copy and paste your design. You can then prepare your model using the printer’s software and start printing. It is easy to make the design fit your imagination, and it can be used in multiple applications.

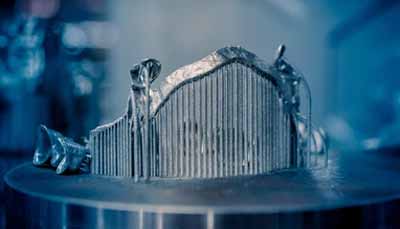

3D Printing with Titanium

When considering what to print on titanium, consider the pros and cons of each. In general, 3d printing titanium several advantages. First of all, it’s an excellent material for 3D printing. Second, the DMLS process uses an unusual extrusion method, which allows for excellent detail and high-end results. Lastly, it’s easy to make repairs on titanium. If you’re looking for a durable, strong, flexible project, you’ll want to go for titanium.

Check Designs before Printing

DMLS machines can make changes to your design file instantly, but they can’t change it later. So, it’s best to check the design before you print. Ensure that you have a clear idea of what you want to make. If you’re not sure about the process, you can check out other processes of 3D printing on metal. The EBM method is gaining popularity among experts as well. It is different than other techniques, and uses a different power source.

In motorsports, titanium 3D printing is becoming an important component for race cars. In addition to reducing weight, it makes vehicles more aerodynamic. The Oxford Brookes Formula Student team, in the UK, worked with the Manufacturing Technology Centre to redesign the uprights of the vehicle. The result was a 50% weight reduction. It’s important to realize that the process of using a DMLS machine is not always suitable for large structures.

Use Titanium 3D Printers

When you’re ready to print on titanium, make sure that you have the correct machine for the job. A DMLS machine is a special type of titanium 3D printer that will allow you to produce the same kind of products as traditional additive manufacturing. This type of material will be printed from your design files, so it’s important to have a file that is formatted correctly. This can help you to make the best possible results in your project.

When you print on titanium, make sure you have an accurate design. DMLS machines are designed to be extremely precise. However, small imperfections on the surface will affect the final product. You should make sure that the design matches the material’s characteristics. If your designs are too complex, you should consider using a different material. You can also choose the right material for your specific needs. You can even use your own custom 3D printer.

Conclusion

The process is not as complicated as you might think. During the entire process, the printer sits inside a clean-room. The staff must wear respirators and overalls to protect their lungs. They remove the build plate powder by hand and sift it out. Once the design is complete, the support structures are removed. This allows for a high-quality, flexible titanium printer. These features make titanium the ideal material for biomedical and aerospace industries.